Biotechnology, organophilic nanofiltration and pervaporation

The versatile use of membrane separation processes in research is a real alternative to established processes. The purity of chemical substances and the avoidance of impurities are of particular importance. At no time during the process may these be changed or even contaminated.

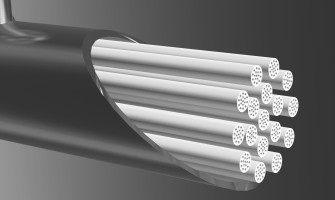

Our membrane plants therefore meet all requirements for sterile and interaction-free work right from the start. The metal-oxide membranes and stainless steel components are manufactured in pharmaceutical quality and are highly stable chemically and thermally.

As a research and development partner, we also offer micro and pilot plants as well as the rental of plant technology. In addition to liquid filtration, systems for vapor permeation, gas permeation and pervaporation are also available.

Your advantages at a glance

- Sterile application due to components that are easy to sterilize

- Processing at standardized pharmaceutical level

- High thermal and chemical stability for flexible use without chemical interactions

- Long durability due to robust components

- Detergent-resistant materials

- High and constant performance due to cross-flow construction

- Scaling according to your needs

- Manufacturer with over 20 years of experience in the design and manufacture of membrane plants

Applications

Membrane plants are very versatile. The following list therefore contains only examples of potential applications in the biotechnology industry.

- Separation of macromolecules from organic and inorganic solvents (peptides, proteins, modified carbohydrates)

- Targeted extraction of cells from liquid phases

- General downstream processes for enrichment of microbiologically produced products

Contact us

Our team is always at your disposal for advice. Send us your inquiry or contact us by phone.